S&S Northern has launched new Carbon Dioxide (CO2) detectors which can be used to monitor CO2 levels in environments such as commercial kitchens, school and food technology classrooms . The CO2 detectors have already been installed in a number of schools and commercial kitchens and Bristol City Council has this month installed 11 detectors in its kitchens.

Keeping kitchen staff safe

All new and refurbished kitchens in the UK are required to meet BS6173 by installing a gas interlock system which ensures that gas is not available in a kitchen if the ventilation system is not working. However some interlocks (not those manufactured by S&S Northern) have an override switch (these are NCS – not to current standard) which means that kitchen staff or maintenance engineers can turn off the interlock if the air pressure differential switch is seen to be faulty. In order to do this, however, it is vital that adequate ventilation is ensured in the kitchen. An effective way to determine this is by continually measuring the CO2 levels in the working area.

S&S Northern’s CO2 detector has been developed in response to Technical Bulletin 140 introduced in April 2012, to offer a means of monitoring CO2 levels whilst keeping the kitchen running if the fans or air pressure differential switches fail. Essentially the gas interlock system should function as specified in BS6173:2009 and a backup system in the form of CO2 detectors should be used in the event of fan failure. The gas interlock system monitors the operation of the fans and shuts down if the fans fail; the CO2 detectors can then be used to monitor the quality of the air in the kitchen.

The CO2 detector works at two levels, 2800ppm and 5000ppm. At Level 1 (2800ppm) the head of the kitchen either needs to increase ventilation by opening doors or windows or reduce the cooking load. If insufficient ventilation is available the CO2 levels will continue to increase and at Level 2 or 5000ppm the gas will be shut off.

A healthy classroom

Good air quality in schools helps improve students’ learning. In highly populated areas such as classrooms, students are breathing out large amounts of CO2, which can lead to students becoming drowsy and lethargic and concentration levels can then drop. The issue of good ventilation and reduced CO2 levels in classrooms is highlighted in IGEM/UP11 and Building Bulletin 101. Both support Building Regulations Approved Document Part F in establishing the air quality and ventilation recommendations for schools.

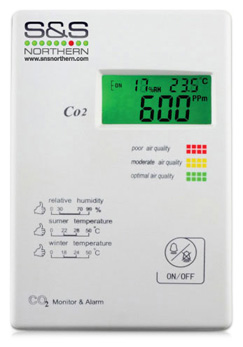

S&S Northern’s CO2 detector helps meet these requirements with their ‘traffic light’ display showing teaching staff the level of CO2 in the room and therefore if action needs to be taken to increase ventilation.

The detectors green display indicates that the CO2 present is within recommended levels. If the level rises above 1000ppm the detector changes to Amber and the teacher should increase ventilation by turning on fans or opening doors or windows, in an effort to reduce the level. If the CO2 level goes above 1500ppm the CO2 detector changes to Red indicating an urgent need to increase ventilation in an effort to reduce it to an acceptable level.

In food technology classrooms where gas is present there are different requirements. Here IGEM/UP/11 section 11.2 states that the average level of CO2 in the teaching area during the working day should not exceed 1500ppm and should never exceed 2800ppm of CO2 at any point throughout the teaching day. In food technology classrooms fitted with a gas interlock system, the gas valve should close and gas should be isolated if the CO2 level reaches 5000ppm.